Classic Ladies Bike Re-imagined

Our vision at Skiens Cykkelfabrik is that the future of transportation has two wheels and a handlebar. With our line of classic bikes we are connecting the past with the future. We are inspired by our vintage bicycle models and re-imagining them. We want the styling to be timeless but with no compromise in quality. The materials should be natural with aluminium, leather and steel. No plastic.

Bicycle Model History

The inspiration for the new Speed ladies bike is in our history books. We had a few historical ladies bikes that all featured timeless curves. These were beautiful bikes that also were enjoyable to ride. A bit heavy bikes for today's standard, but the ride feel and styling was great.

These historical ladies bike models, literally called “model lady”, is what we are now re-imagining. We are calling this new model Speed Curve and it will appear as a new model next to our single speed bike Speed ONE.

Speed Curve Design Direction

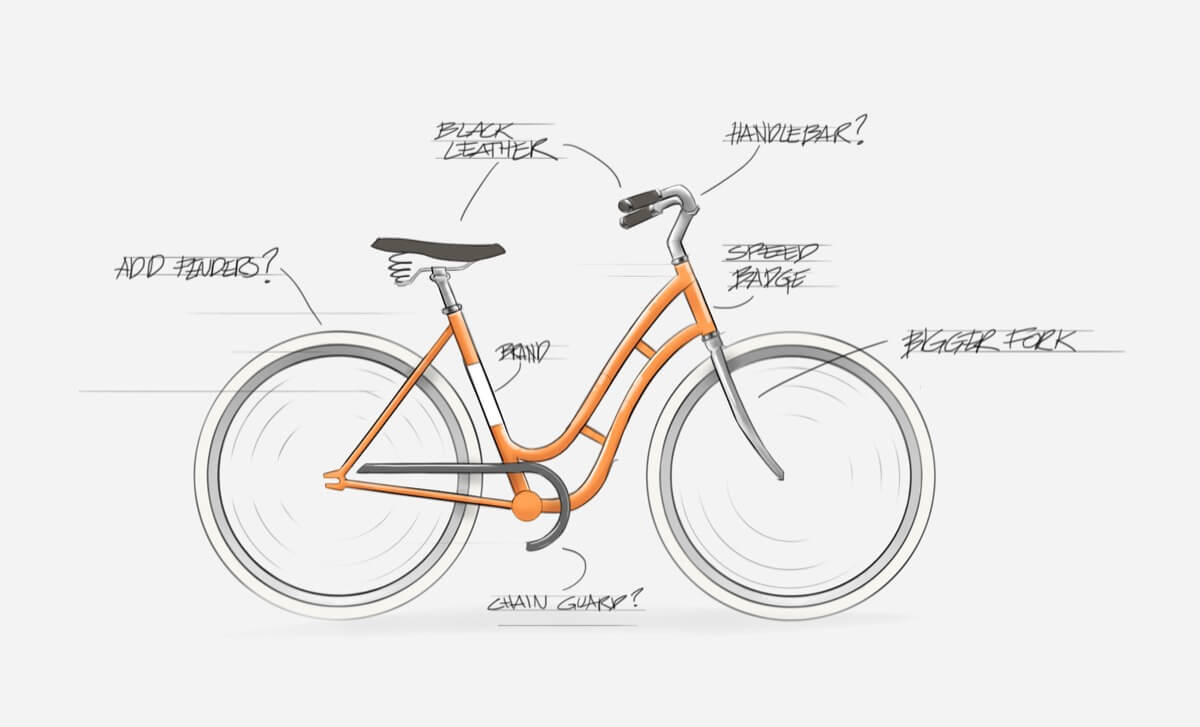

We are working with Snowball in the product design process and the initial input from us was to follow the curved styling of the historic bike model. The styling of Speed Curve should be timeless. Design & styling first, but with no compromise on quality. None.

The initial sketching of the new ladies bike model Speed Curve shows exactly this. A desirable beautifully curved ladies bike.

CAD Product Design

We have imaged a ladies bike with timeless style. The next step is the bicycle engineering. We need to make sure we engineer this in our prefered materials including light and strong aluminium, natural colored leather and steel. Oh, and titanium. No plastic.

To engineer the ladies bicycle Speed Curve we are running a CAD product design process with Snowball. Details matter like the bicycle dropout and seat clamp are being designed and engineered in detail. Both are of course designed and customly manufactured by Skiens Cykkelfabrik. Speed Curve will of course also feature our custom-made 700c white tires.

Classic Ladies Bike Visualized

In the engineering process we are using CAD modelling and are rendering out visualization of the bike in a high level of detail. We are using some components from other vendors like internal hub gears and brakes, but many of the components are either custom-made by us or we are working with partners for custom parts like the custom leather saddles by Tabor and custom crank and chainring.

At this point the renders are just teasers as we have not decided on all details. But the level of detail is important. No compromise.

Bicycle Prototyping and Testing

At the time of writing we are on our second round of physical prototype frames and we have been riding the bike for a bit more than six months. We have tested several types of gears, brakes, handlebars. The ride is supersweet. Promise.

We cannot wait to get this on the market.